BW Series

BMG 1080BW

BW Series

BMG 1080BW

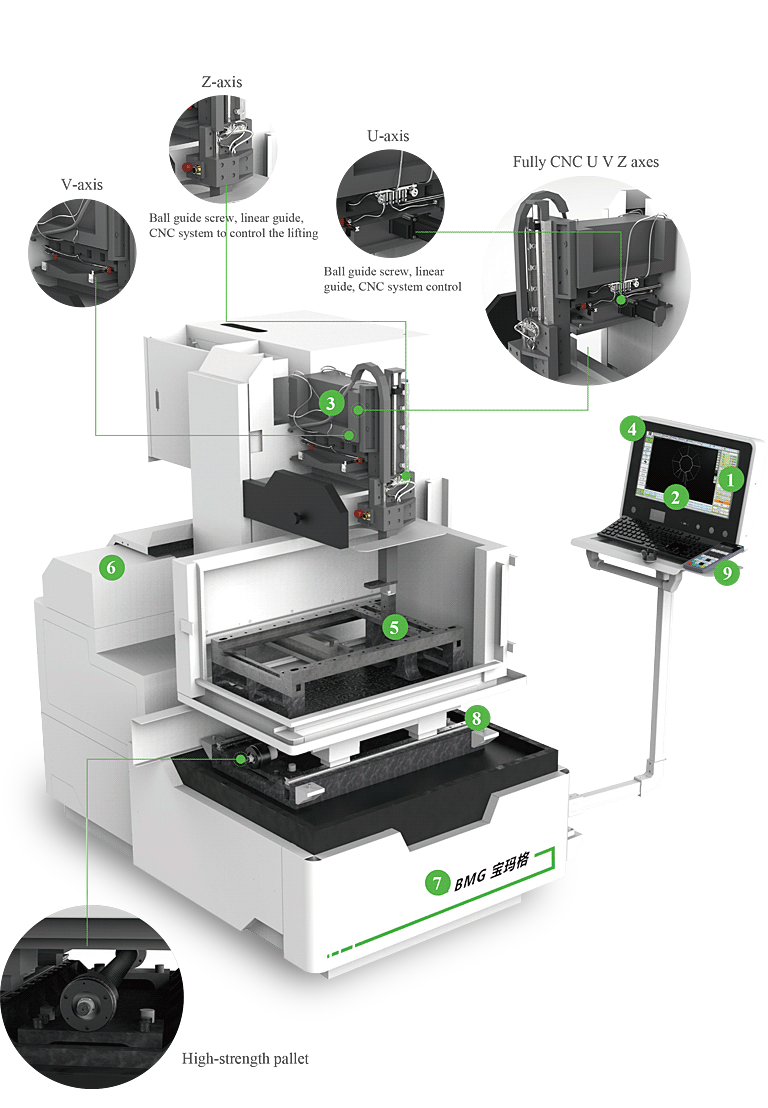

- The U, V and Z axes are manufactured according to the X, Y axes standard.

- Human-machine dialogue, ordinary operators quickly become professional masters.

- Comply with TUV CE comformity, both safety and desired design with easy operation.

Specification

BMG 1080BW

Workbench Size

1780 x 1172 mm

Table travel (X*Y)

1000 x 800 mm

Z-axis travel

500 mm

Travel of U, V Axes

70 x 70 mm

Maximum cutting thickness

500 mm

Maximum load

5000 kg

Standard cutting taper

±10°/100 mm

Diameter of molybdenum wire

0.1-0.2 mm

Multi-knife cutting accuracy (Cr12, S=40)

≤±0.005 mm

Repeat positioning accuracy

≤±0.005 mm

Optimum surface roughness

Ra≤0.8 (Optional 0.4) μm

Processing efficiency

100-220 mm²/min

Dimension(L*W*H)

2962 x 2400 x 2495 mm

Weight

≈6050 kg

Electrical power consumption

3 KVA

Motors of each axis

X、Y axes : Servo Motors, U、V、Z axes: AC Subdivision Motor

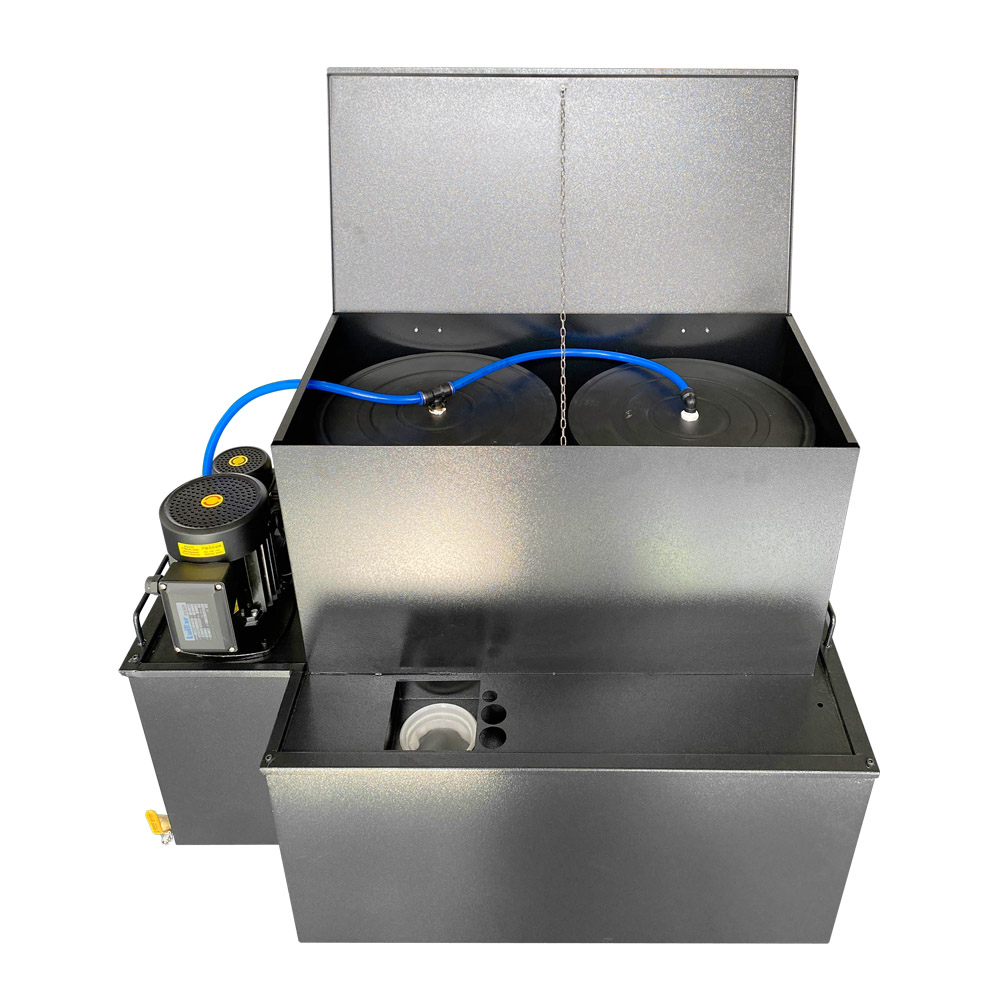

Dielectric Tank

Tank capacity

120 L

Deionzer

Auto

Filter element

2 pcs

Features

Mechanical Structure-1080BW

1. BMG-cut programming software

- Corner clearing assist: after opening the corner clearing function in the main interface, you can select and set relevant corner clearing settings, and you can machining samples to deepen your understanding;

- Coding auxiliary: compare and modify the code value brought in from the main interface to control the identification and application of the software, such as M00 pause;

- Auxiliary function: turn on and set the corresponding auxiliary function

a. Cut-in line arc transition: After opening and setting, add arc transition at the cut-in lead to correct the cut-in smoothness;

b. Inner hole avoidance arc segment: After opening and setting, add arc transition at the cut-in trajectory to correct the smoothness of the trajectory;

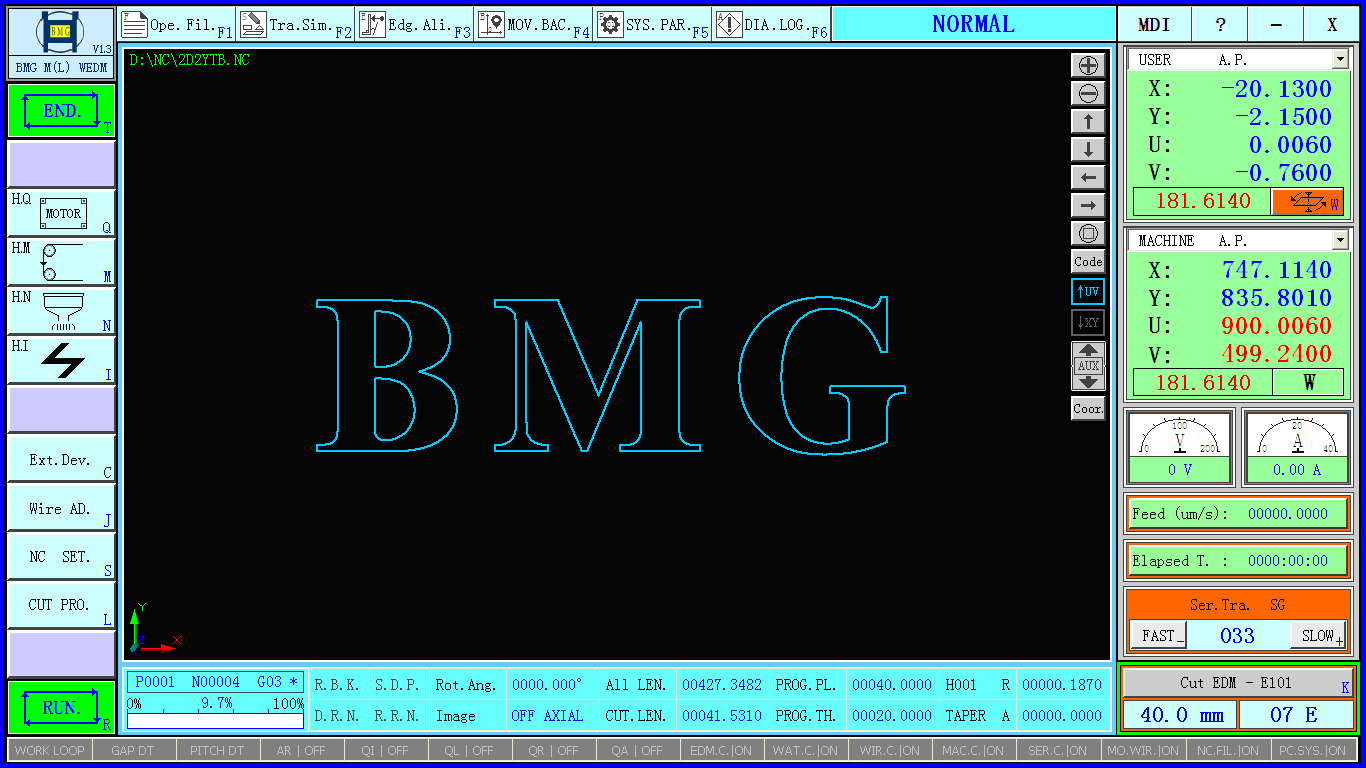

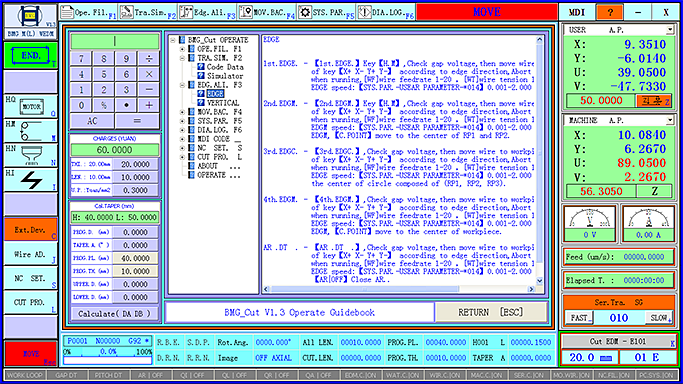

2. BMG WEDM-LS five-axis control system V1.3

- The best calculation accuracy is 0.01 μm

3. Five-axis high-strength and high-precision mechanical transmission

- X Y U V Z five-axes adopts high-strength ultra-precision linear guide; C3 grinding grade ball screw; Semi-closed loop and fully-closed loop control system, professional laser detection and compensation, to achieve ultra-high step accuracy; Realize high-precision taper machining;

4. Processing database

- Through years of actual machining data and R & D current and voltage sampling, discharge high-frequency EDM achieves ultra-high stability and consistency. It has low requirements for professional operators and solved the persistent problem of poor consistency of processed products. The database realizes man-machine dialogue. Qualified products can be processed after entering processing requirements.

5. WEDM-LS type high-strength workbench

- The BMG WEDM-MS workbench adopts the same casting process as the WEDM-LS, with high-strength and high-precision support, which is convenient for clamping and easy operation.

6. Wire conveying parts

- The wire conveying adopts the same level of linear guides as XYUVZ, high rigidity, and high-grade photoelectric switches are used for reversing and limit position. The real non-contact reversing ensures the smooth reversing of the wire drum and improves the cutting stability of the machine tool.

7. The machine tool

- It adopts resin sand casting, WEDM-LS structure process, and secondary tempering treatment. After more than six months of natural aging treatment, the accuracy of the equipment is guaranteed for long-term use.

8. Ball guide screw and linear guide

- Adopt HIWIN, PMI, THK linear guide and ball guide screw to ensure the accuracy of the machine tool for more than 10 years.

9. Mobile manual control box

- It adopts imported electronic original switch, and is made of film. It has many functions such as XY coordinate display, axis shifting data conversion, function switching, high-frequency switch of water pump and so on. It is very convenient to use, waterproof, oil-proof and anti-fouling, long service life and low failure rate.

10. Water retaining cover

- The water retaining cover adopts the folding and push-pull method, which is easy to use, without water leakage and water seepage, and keeps the working environment on site clean.

11. Environmental protection water tank

- The whole machine adopts 0.007mm double filter, φ340×300, no sewage discharge, regular replacement to protect the environment and solve the environmental protection problems of enterprises.

Auto Measurement System

AC CUT HMI

- The intuitive and orderly interface is more convenient for users to learn and master quickly.

- With the newly designed ” One Hand Operation ” mobile control box, multi cavity programming and rapid setting of various processes can be realized.

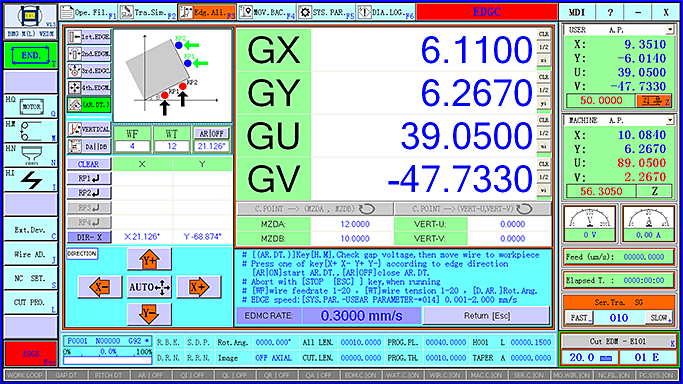

- Using automatic measurement system, you can be able to find the inclination measurement, AR correction and reference point. BMG provide a probe to measure the accuracy and auto-calibrate the precision mold before machining which reduce the pre-processing time.

- With macro instruction, it automatically measure and correct the reference point to improve the mold processing accuracy. After processing, the accuracy test is performed directly on the workbench, which saves the repeated disassembly time of the workpiece and avoid the processing errors caused by repeated disassembly.

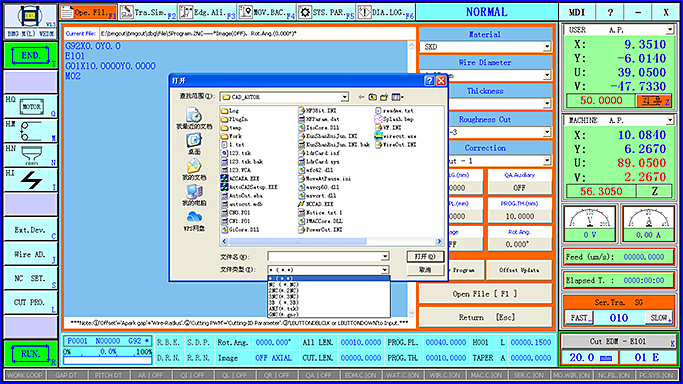

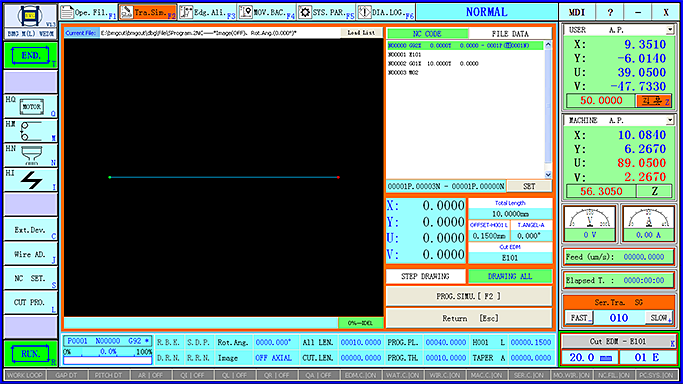

1. File management

- Manage multi format processing files, can check and correct the selected files to be processed, such as code, compensation, etc. Preset the select processing intelligent auxiliary items, make optimal processing for special angle clearing, graphic rotation, mirror image, etc. The simple program setting without programming makes the processing more convenient. One click compensation update function makes the matching accuracy easier to control. Support a variety of code formats, integrate the simplicity of WEDM-HS, the practicality of WEDM-MS and the intelligence of WEDM-LS, the selection of programming master workers will be more handy.

2. Prepare machining program

- Simulate the code files being processed or to be processed, check and verificate to make preparations before processing.Check program limits and related process parameters.It supports the rapid conversion of code into graphics to check the offset interference and the physical contour of the model. It can also be run in a single segment to check the code and the corresponding program segment data.

3. Execution and detection

- A variety of automatic reference search methods allow users to complete the correction more quickly and efficiently. The high intelligent AR function makes the WEDM-MS and WEDM-LS convenient and efficient at the same time. Preset vertical point, automatic vertical alignment, one key reset, etc.

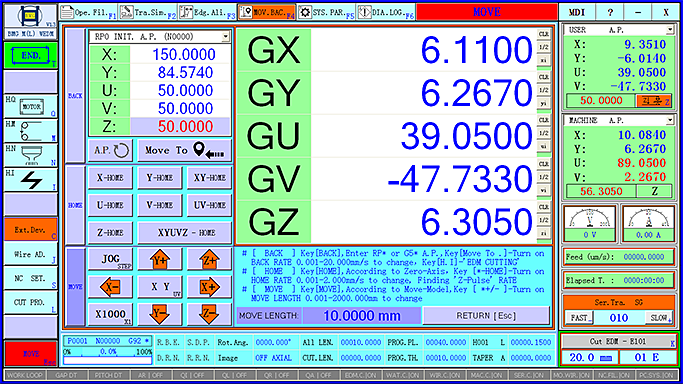

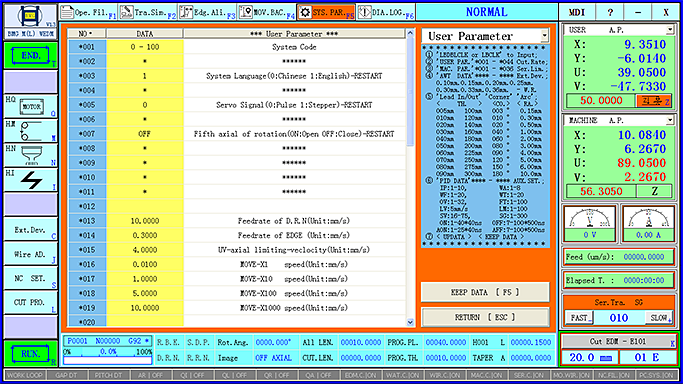

4. Manual mode

- Enter the main function execution setting interface of the machine tool. Implement the management settings of user parameters, mechanical parameters and other related functions. Allows you to set and perform operations related to Chinese and English windows and axis shifting speed. Set the necessary parameters and coordinate display mode of taper machining. It is allowed to set and execute the settings of relevant mechanical pitch compensation parameters, elevant test data tables can be modified, entered and used.Set the mechanical travel and set the type selection of shaft.

5. Management and return to zero function

- Manage the consumption of EDM wire, deionized resin and filter. Allows users to set preferences and adjust user personalization.It allows to set and calibrate machine functions, perform work axis reset and return to mechanical origin. Displays the current system settings and allows multiple system updates.

6. Operation Guide

- Detailed instructions make it easier for operators to learn the operating system.

Spare Parts

Spark Erosion Meets Manufacturing Efficiency

Molybdenum Wire

0.18mm Molybdenum Wire S Type for CNC High Speed and Middle Speed Wire Cutting EDM WEDM Machine

| Product Name | Diameter | Length | Place of Origin |

| Molybdenum wire | 0.18mm | 2000m | China |

High Precision Linear Guide Rail

All five axes adopt linear guide rails to ensure the machining accuracy

Panasonic Servo Motor

Panasonic servo motor ensures the stability of processing

Panasonic Frequency Transformer

Panasonic frequency converter has low failure rate, strong usability, more intelligence and low noise

Electrolytic-free High-frequency Power Supply

The electrolytic-free high-frequency power supply independently developed by BMG has stable processing pulses and ensures the surface finish of the workpiece.

Product Parameters

| General Product Parameters | |||||||

| Model | BMG430A | BMG530W | BMG530BW | BMG640W | BMG640BW | BMG850BW | BMG1080BW |

| Workbench Size (mm) | 720×520 | 779×529 | 920×654 | 879×579 | 1050×717 | 1520×762 | 1780×1172 |

| Worktable travel (W*L) (mm) | 400×320 | 500×350 | 500×350 | 600×400 | 600×400 | 800×500 | 1000×800 |

| Maximum cutting thickness (mm) | 280 | 300 | 300 | 300 | 300 | 400 | 500 |

| Maximum load (kg) | 300 | 500 | 600 | 800 | 900 | 1500 | 5000 |

| Z-axis travel (mm) | 200 | 300 | 300 | 300 | 300 | 400 CNC | 500 CNC |

| Travel of U, V Axes (mm) | 15×15 | 70×70 | 70×70 | 70×70 | 70×70 | 70×70 | 70×70 |

| Standard cutting taper (°/mm) | ±3°/100 | ±10°/100 | ±10°/100 | ±10°/100 | ±10°/100 | ±10°/100 | ±10°/100 |

| Diameter of molybdenum wire (mm) | 0.1-0.2 | ||||||

| Multi-knife cutting accuracy (mm) (Cr12, S=40) |

≤±0.003 | ≤±0.003 | ≤±0.003 | ≤±0.003 | ≤±0.003 | ≤±0.005 | ≤±0.005 |

| Repeat positioning accuracy (mm) | ≤±0.002 | ≤±0.002 | ≤±0.002 | ≤±0.002 | ≤±0.002 | ≤±0.003 | ≤±0.005 |

| Optimum surface roughness(μm) | Ra≤0.8 (Optional 0.4) | ||||||

| Processing speed (mm²/min) | 100-220 | ||||||

| Dimension(L*W*H) (mm) | 1818x1550x1870 | 1781x1593x2028 | 1781x1660x2030 | 1905x1715x2030 | 1920x1750x2100 | 2190x2100x2780 | 2962x2400x2495 |

| Weight (kg) | ≈1800 | ≈1900 | ≈2050 | ≈2200 | ≈2500 | ≈3260 | ≈6050 |

| Electrical power consumption (KVA) | 3 | ||||||

| Work tank capacity (L) | 120 | ||||||

| Kind of motors | step | servo | servo | servo | servo | servo | servo |

Our Service

Our Service

- The samples can be processed according to the drawing requirements for free.

- The machine (including hardware and software) can be customized according to customer requirements.

- Provide free technical guidance and operation training to customers (including remote video and face-to-face).

- Machine parts (except worn parts) enjoy two-year warranty.

- If special problems cannot be solved through remote video, we will conduct door-to-door debugging and technical guidance according to the actual situation.

- Our purpose: Help customers become the NO.1 in the industry!

FAQ

FAQ

- Q: It says the machine has automatic vertical alignment. How does it work?

A: When you press the vertical automatic calibration button, the machine tool will automatically tilt the molybdenum wire to the edge of the upper part of the workpiece first, and then to the edge of the lower part of the workpiece. Finally, the system will automatically make the molybdenum wire parallel to the required machining surface after calculation, which can realize the automatic verticality calibration function. Please note: the upper and lower edges of the workpiece cannot be chamfered, and the surface of the workpiece must be flat. Otherwise, it is not recommended to use the vertical automatic calibration function, then you can manually calibrate the perpendicularity as usual.

- Q: In software pictures everything is in Chinese, can be changed to English?

A: Yes, the system can be set to all English.

- Q: I’m interested to know more about transit wheels and tension system, usually tension at wire becomes a problem.

A: The WEDM-MS is equipped with a mechanical tension mechanism as standard, and the WEDM-LS is equipped with an automatic tension sensing system, the material of the molybdenum wire is different from that of the brass wire, so their own tensile force are also different. After the molybdenum wire is installed, if the requirements are high Basically, the tension needs to be adjusted after 48 hours until the next replacement!

- Q: Does your machine use ruby or diamond nozzle?

A: Yes, we use BMG diamond nozzle.

- Q: What’s the life time of nozzles and wheels?

A: Usually it needs to change the wheels after 3 months, and about 1 year need to change the nozzle, while the exact life time is according to the material of workpiece, use times and strength.

- Q: Machines from other factories have a small problem with Z-axis, it moves up and down but is not totally vertically, what about yours?

A: The Z-axis part of our host adopts a linear guide to move up and down, so it can ensure that the Z-axis moves vertically up and down during processing.

- Q: About software and cpu maintenance: Does the software runs on Windows? And if software fails? Does machine has it’s own backup?

A: About the maintenance of software and hardware: it runs on Windows, and the hardware goes through strict repeated inspection and aging test before leaving the factory to ensure stable operation in the later stage; the software has one-key restore backup and archive backup, which can easily repair the faults caused by viruses and abnormal loss of files.

- Q: It says optional 0.4 roughness, what’s the meaning? Does it need an extra accessory?

A: The normal accuracy of our WEDM-MS is 0.4-0.8. The surface roughness is related to the material of the workpiece and the experience of the operator, but it will not exceed 0.8, (for example if the workpiece not very thick and operator has enough experience then also can process the surface to 0.4). If it needs to reach 0.4 steadily, I suggest that it needs to be modified, or our low-speed wire cut EDM machine tool can be used directly.

- Q: Your machine is ready for all materials?

A: Yes, our machine is ready for all materials which can be processed electrically. The processing database is one of our unique advantages. The database of our system has a large amount of actual processing application experience and related parameter libraries that can be used or referenced.

- Q: If I need to cut aluminum materials, is your machine equipped with aluminum cutting device?

A: Yes, there are device options for processing aluminum materials.

- Q: What do you mean with graphic rotation?

A: After the workpiece is installed, the system can easily obtain the reference datum, and then process it without tedious disassembly and assembly to move the workpiece to the specified parallel or vertical state.

- Q: Does the machine has his own drawing software? Or need to use an external software?

A: Yes, the system is equipped with our self-developed graphics code processing program based on CAD, so you can draw directly in our software and use it like CAD, or you can choose other wire cutting programming software with G code storage applications. And five programming formats are supported, such as (NC, 2NC, 3NC, 3B, ANJ)

- Q: Does x/y/u/v/z are stepping or servo motors?

A: Except that A series is stepping motor, W and BW series are servo motors.

- Q: About lubrication system , is it manual or automatic? Does it use oil or grease?

A: The high-frequency moving parts are lubricated by automatic oil supply and timing, and the low-frequency moving parts are lubricated by centralized grease storage.

- Q: Max taper is 10°?

A: The maximum taper for basic machines is 10 degrees, but we can also customize larger tapers according to your requirements.

- Q: Tell me more about technical assistance ? Do you have a specialized department to help us if we need help?

A: We have a professional after-sales team and strong technical support. We will respond and solve any professional problems at the first time. In case of special problems that cannot be effectively solved remotely, we will also arrange after-sales technicians to arrive at the site for solution.

Accessory

Standard Accessories

- Five axis all linear guide rail

- Molybdenum wire x 1 spool

- Tool Box

- BMG Diamond nozzle x 2 pcs

Options

- Sixth Rotating Axis

- Magnetic levitation linear motor

- Roughness Ra0.4 device

- Aluminum cutting device

Search